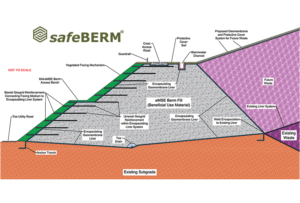

Our encapsulated mechanically stabilized earthen (eMSE) berm system design, safeBERM® goes beyond any traditional MSE berm design by incorporating additional safety factors. By integrating macroencapsulation, proactive liquids management, flattening out the exterior slope, and providing easy access the safeBERM® system provides protective features unmatched in today’s market.

Efficient Use of Space

The Creation of Opportunities

By Design: Preserving the Environment

By Design: Preserving the Environment

Mount Trashmore Park

Sports Complex

Warehousing

Reuse of Non-Traditional Materials to Reduce Construction Costs

By Design: Cheaper

Construction Material: CCR

Construction Material: Impacted Soils

Construction Material: Incinerator Ash

Construction Material: Non-Recyclable Materials

Construction Material: Dredge Spoils

Is your organization prepared with the right tools?

In this economy, EnCAP-IT’s technology has proven to be a “breath of fresh air” in Waste Industry’s struggle to provide solutions increasing value, sustainability, and profitability while maintaining the highest environmental stewardship for the communities in which we operate and serve.

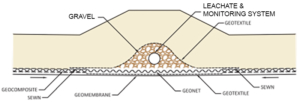

The simple idea of full encapsulation within the MSE berm is tremendously advantageous to the customers by reducing the financial burden of this type of capital expenditure. This provides “smaller” landfill operators (private or public) the ability to initiate this type of project.