Efficient Use of Space

The Creation of Opportunities

By Design: Preserving the Environment

By Design: Preserving the Environment

Mount Trashmore Park

Sports Complex

Warehousing

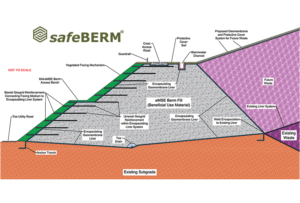

Reuse of Non-Traditional Materials to Reduce Construction Costs

By Design: Cheaper

Construction Material: CCR

Construction Material: Impacted Soils

Construction Material: Incinerator Ash

Construction Material: Non-Recyclable Materials

Construction Material: Dredge Spoils

Is your organization prepared with the right tools?

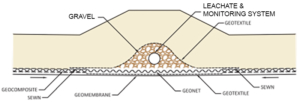

EnCAP-IT’s technology maximizes the excavated inflow rate, minimizes the dewatering, and onsite hauling distance. This allows my equipment enough “lay down” space to stay ahead of unencumbered excavation. Encumbered excavation costs me time and money.

The method of individually wrapping the cells (bunkers) allows for the acceleration of capping the excavated ash. This avoids future contact water created by weather or natural disasters.