Maximize Innovation Before Resorting to Traditional Methods

In 2008, the Tennessee Valley Authority’s dike containing its coal ash failed, allowing approximately 5.4 million cubic yards of coal ash to spread over 300 acres and into the Emory River. Since then, the problem that coal ash represents for the U.S. has only gotten worse. Constant battles between federal and state governments, regulatory agencies, environmental groups, courts, vendors and the general public represent the inability of these stakeholders to understand how monumental this situation has become.

Since that devastating TVA spill brought the situation to front pages everywhere and other localities have dealt with their own coal ash disasters, several facts have been proven:

- CCR is a waste containing arsenic, mercury, lead and other toxic substances. It may not be officially classified as hazardous waste, but it is hazardous to the environment. That’s not something Washington, D.C., can change through legislation.

- Liquifying and pumping wet coal ash into unlined containment ponds may not pollute the air, but the moisture facilitates toxins leaching into surrounding soil and groundwater.

- Capping ponds in place is not an option if the coal ash will remain in contact with soil, which is usually the case.

- Drying and excavating coal ash ponds generates tremendous volumes of coal ash requiring proper deposition.

- Any disposition strategy must address these questions: how to dispose, where to dispose, and for how long?

- The longer the distance coal ash must be transported by road, rail or barge for off-site disposition, the greater the likelihood that it will disrupt and impede regular traffic or have a spill that creates another environmental mess to clean up.

We’re already developed various methods to tackle this challenge.

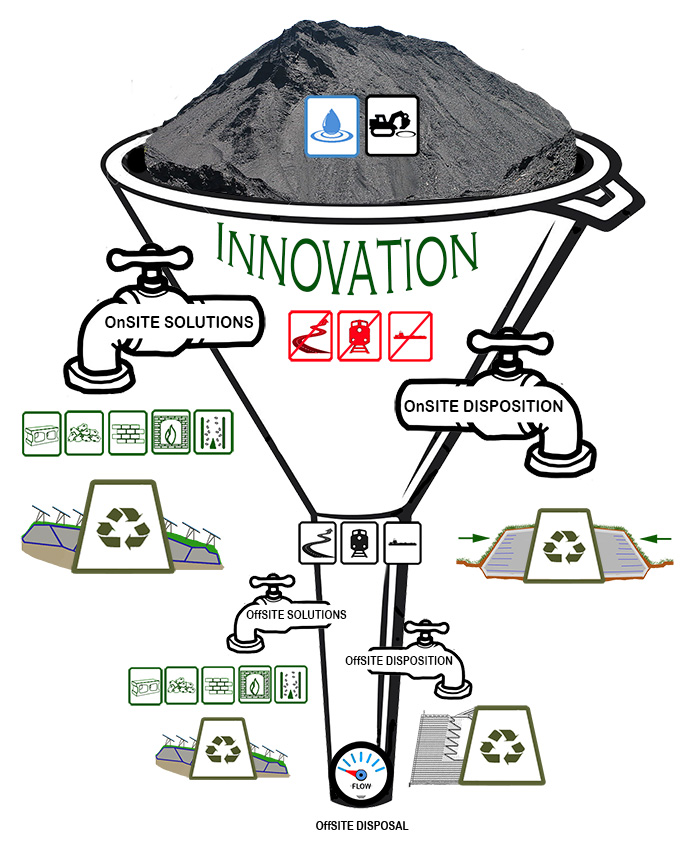

INNOVATIVE ON-SITE USES:

Microencapsulation involves recycling coal ash into other products, such as brick, block and cement. When coal ash becomes physically bonded to other ingredients, it’s rendered inert and harmless. This solution is limited only by market demand for building materials. Developing other uses for coal ash in other industries could only help to use up the existing stockpile.

Macroencapsulation offers several approaches and solutions. When coal ash is transferred on-site to a fully lined landfill, that land can be reclaimed for solar farms or sports parks that entire communities can enjoy. Another on-site option is using the coal ash as fill to create new solid waste landfills, helping communities achieve more capacity for household waste disposal by re-purposing land that’s already otherwise unusable.

INNOVATIVE OFF-SITE USES:

Macroencapsulation becomes a highly versatile solution when coal ash can be transported off-site to be used as fully encapsulated fill for solar farms, berms or other structures. Also, it can become fill around existing solid waste landfills to increase their airspace and extend their useful lives. However, the coal ash must be transported with the same risks as mentioned above, not to mention the added expense.

TRADITIONAL OFF-SITE USE:

Disposal is the last resort if all these other methods don’t pan out, with the coal ash ending up in a subtitle D compliant landfill.

Until the country weans itself completely from fossil fuel energy, coal ash will continue to be generated and legacy coal ash needs to be beneficially reused or stored properly. Now is the time to figure out the best ways to dig ourselves out from under the 500 to 600 million tons of legacy coal ash we’ve already created while building up capacity and infrastructure to implement innovative solutions for the future.

Our ultimate goal should be no coal ash left behind. Every existing pond needs to have a plan in place for its productive disposition.