It seems hard to believe that Utilities, EPA, State Politicians, Regulatory Agencies, environment groups, and the public around the country have been wrestling with this issue of what to do with legacy CCR for almost 12 years. Still even harder to believe is that the nation is making progress.

Despite the emotion of it all, certain fundamental approaches and strategies have been developing. In this post, we will identify all the factors associated with these challenges. We even graded them from an overall safety perspective. The criteria have a waterfall effect; safety first, then delivery and cost.

Safety – At EnCAP-IT, we believe in “safety first.” Whether it is the safety of employees or the safety of the environment, the solution needs to meet or exceed the CCR rule requirements and in the site’s state or local expectations. Our grades are based on the maximum environmental safety the solution provides.

Delivery –The solution’s delivery is another aspect to consider in its overall “grade.” The three factors our team focuses on are constructability, required permitting, and the approval process. The plan to construct any of these methods requires planning and an abundance of materials. It may seem obvious, but something can’t be constructible if it cannot be permitted or approved by all stakeholders.

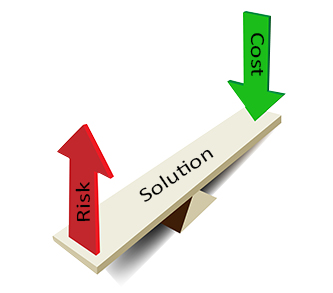

Risk & Costs –When final decisions are made, risk and costs matter. Whether it is a concern of reimbursement, bottom line, or environmental risk of the solution, the risk and costs associated with decisions must be considered. Risk and costs often have an inverse relationship. For example, while excavating and closing by removal mitigates the long-term environmental risk and liability for utilities, but it comes at a higher cost, and increases the challenges for reimbursement. So, capping the CCR in place has the lowest costs, but the utilities retain the highest long-term environmental and reimbursement risks.

Like a childhood cog and wheel puzzle, utilities are challenged to move these three factors around until a solution that meets the different criteria and is approved by all stakeholders is found.

Methods:

With clear criteria in place, let’s look at the deposition methods:

| Deposition Method | Description |

On/Off Site |

|---|---|---|

| Cap-In-Place | “Cap in place,” or “closure in place,” is the practice of leaving an industrial waste impoundment in place and covering it with both earthen and synthetic materials. | ON SITE |

| Hybrid Cap-In-Place | The ash basin footprint is consolidated by adding stability berms and hydro-static barriers. Then the Cap-In-Place method is utilized in the remaining unlined area within the center of the new footprint. | ON SITE |

|

Beneficiation [Closure by Removal] |

This Encapsulated Beneficial Use method binds CCR into a solid matrix, minimizing mobilization of trace metals into the environment. Common applications of this encapsulated recycling process include the creation of building/construction products such as brick, aggregate, or processing of the CCR to meet fly ash standards for Portland cement (PC) substitute in concrete. | ON SITE |

|

Structural Fill [Closure by Removal] |

Application as a structural fill, to bring property to final grade. For example, this method is predominantly advantageous in “valley fill” coal ash basins where natural steep slopes prohibit land reuse. | ON SITE |

|

New Landfill [Closure by Removal] |

Application to construct new waste management footprint using traditional construction methods. Suitable land is available to site a greenfield landfill on existing or adjacent property. | ON SITE |

|

Expansion of Existing Landfill [Closure by Removal] |

Expand existing permitted onsite landfill by vertical or horizontal expansion methods. | ON SITE |

|

Basin Retrofit to Landfill [Closure by Retrofit] |

This application utilizes the current basin footprint, a quasi-waste footprint using traditional landfill construction methods on land that has already been environmentally impacted. | ON SITE |

|

Beneficiation [Closure by Removal] |

Same as On-Site Beneficiation but excavated CCR is transported to an off-site facility for processing. | OFF SITE |

|

Structural Fill [Closure by Removal] |

Same as On-Site Structural Fill but excavated CCR is transported to fill for placement. | OFF SITE |

|

Landfill Disposal [Closure by Removal] |

Same as On-Site Landfill but excavated CCR is transported to landfill for disposal. | OFF SITE |

It is not easy when developing a strategy for proper CCR deposition. Utilities have the resources, tools, and stature to jump-start any CCR deposition project by considering all their options so they can guide stakeholders toward wise decisions and action.

In our experience, the right “fit” is when these three criteria work together to form the best solution for your CCR site. EnCAP-IT has 25 years of experience in the waste industry, providing solutions that fit landfill and CCR operators’ needs.

In the next post, we will grade and supply costs to the different approaches using data we have collected over the past 12 years.