M

echanically stabilized earthen (MSE) berms are a practical technique for expanding capacity in existing landfills. Unfortunately, there are some common misconceptions about their use prohibiting the proliferation of MSE berms at landfills. One of the main misconceptions is that MSE berms “are not safe”.

Over the past several years, encapsulated mechanically stabilized earth (eMSE) berms have been developed to make these structures SAFER.

History of MSE Berms at Landfills

The first use of a MSE berm in a landfill application was in 1986 for vertical expansion of an industrial waste landfill in Alabama. An MSE berm using geosynthetic reinforcing was introduced to the municipal solid waste market in 1996, with the design and construction of the first MSE berm at the Pottstown, Pa., landfill. Since then the use of MSE berms at landfills has proliferated.

Despite continued use of accepted design guidelines, along with a preponderance of literature on all aspects of MSE berms; including stability and construction aspects, misconceptions have continued to linger around.

Misconception: Not Safe

Because of the daunting size, especially the height of MSE berms that are constructed for landfill expansion are often, by the public, deemed unsafe. While each landfill facility is unique, all sites have a stringent landfill CQA program for MSE berm projects that regulates the design and construction. Despite this safeguard traditional MSE berms still require free-draining sands and gravels because potential infiltration of stormwater or leachate may increase the pore pressures within the berm. Putting an emphasis on moisture control in MSE berms.

eMSE Berms – Proactive Control of Moisture

The eMSE berm design innovation developed by EnCAP-IT uses “macro-encapsulation”, in which the berm fill is fully encapsulated using a geomembrane liner system to proactively control the infiltration as well as greater flexibility with regards to berm configuration.

eMSE Berms – Stability by Design

In an eMSE berm system pore pressure surcharge is not expected to be a problem during the lifetime of the berm, provided the angles of interface friction and/or adhesion meet the specifications for internal and global stability. The eMSE berm system not only maximizes moisture control, but it also offers the owner more flexibility in the fill materials that can be specified for the project.

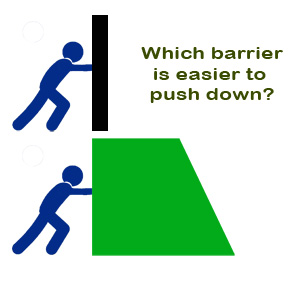

An eMSE berm design allows the use of more economical fill materials as well as greater flexibility with regards to berm configuration. The limitations under traditional design are not present, leaving designers to maximize the size and shape of the eMSE berm. The heavier and wider a berm is, the higher stability safety factors.

Don’t fight traditional MSE berm misconceptions; utilize an eMSE berm system and leapfrog past them!

MAXIMIZE FOOTPRINT

BUILD CAPACITY