Project Costs Matter

When it comes to legacy CCR disposition (see Part 1), project costs need to be considered. The method deemed “most feasible” should not only reflect the science behind the decision, but also how project costs become a factor in the decision process. Whether a utility is regulated or not, costs passed on to ratepayers in regulated markets, or customers in unregulated markets, affect the process.

No one intentionally wants to spend more than they must, so utilities that have legacy CCR, environmentalists, legislators and energy end users do share common goals for incurring reasonable expenses for the solution, which often results in taking a hybrid approach to protect ratepayers or customers by maximizing economies and by preventing unnecessary costs.

Main costs components of proper legacy CCR deposition have major and minor differences. This post covers the major differences, which are:

- Preparation for transport – excavating, drying

- Transportation modes – different for microencapsulation, macroencapsulation and disposal

Common Costs

Although no two coal ash ponds are the same, any clean closure project has common methods:

- CCR de-watering and treatment

- CCR excavation

- Preparation for transport

- Transportation costs (on-site or off-site)

- Final use (costs associated with beneficial use) or disposal

- Site upgrades, restoration

- Ongoing maintenance

On-site handling, site restoration, load-out and project management have similar characteristics and minor differences in costs, but would be consistent in all project scenarios.

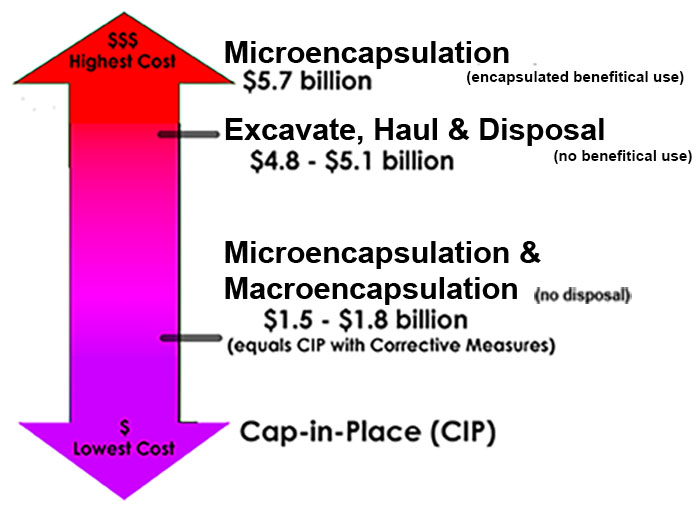

The table below is a comparative example of estimated project costs for the three methods: