Despite years of controversy …. All stakeholders (utilities, EPA, politicians, state regulators, environmental groups, and local communities) will have to decide on “dig it up” or “cover it up” as a middle-path solution. When that happens, the stakeholders will have to make choices as for the methods to deploy. In all these discussions of coal ash disposition — either through beneficial reuse or keeping it intact but contained — the overriding concern is safety.

The cap-in-place solution has been solidly debunked from a safety standpoint. The market for beneficial use of coal ash in building products still lags far behind the over-abundance of legacy CCR. Yes, the market may eventually catch up, but leaving toxic CCR in the ground indefinitely while it waits for a new home isn’t an option.

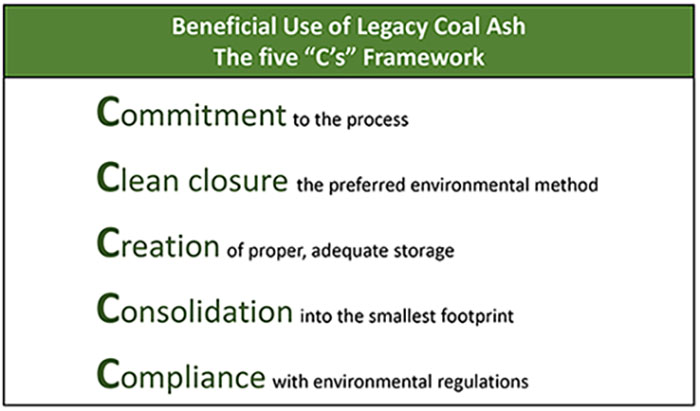

But before any strategy can be developed the stakeholders must decide on what framework in which to proceed. A small paradigm shift in thinking will reveal plenty of choices for the safe storage of legacy excavated coal ash, despite the overabundance of it.

The 5 C’s of Legacy Coal Ash Beneficial Reuse

When utilities are determining how to eliminate environmental hazards posed by legacy coal ash, the paramount goal should be to beneficially reuse much or all of it, if possible, with off-site disposal/storage being the last resort.

Creativity, ingenuity, and innovation is the answer to find a middle-path, but it takes all stakeholders to embrace change.

Innovative Solutions Are Going to Take Priority

Future Beneficiation Warehousing

Beneficiation involves recycling coal ash into other products, such as brick, block, and cement. When coal ash becomes physically bonded to other ingredients, it’s rendered inert and harmless. This solution is limited only by market demand for building materials.

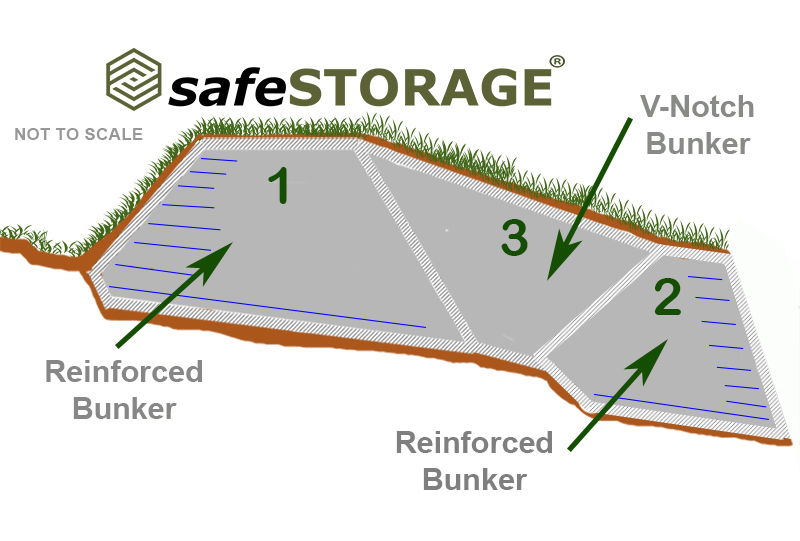

Developing safe on-site storage of excavated ash to extend the beneficiation plant well beyond the regulatory deadlines is an effective way increase beneficial reuse. Bringing the beneficiation plant to the feedstock supply will significantly decrease the economic burden of pre-production transportation costs.

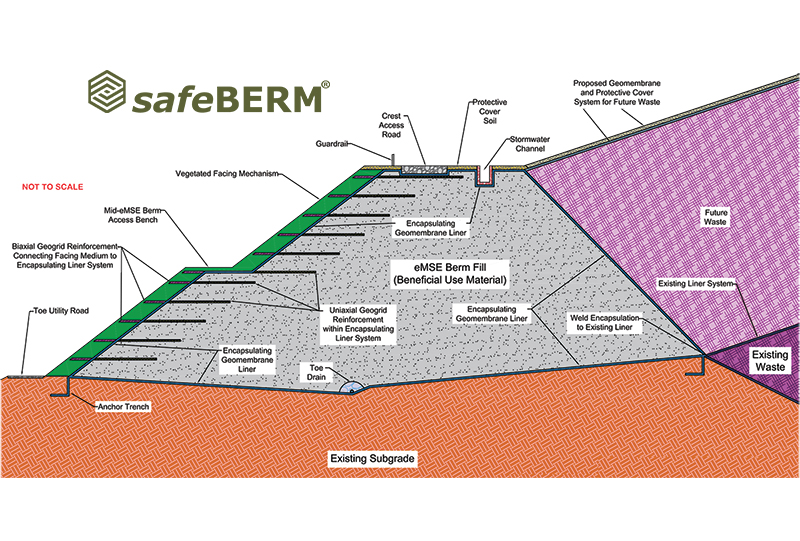

safeSTORAGE® and safeBERM® systems offer several approaches and solutions for facilities that have limited footprints with or without landfills, or stability issues … looking to safely store their excavated ash.

Going Vertical

The land is limited, especially when considering the regulations surrounding legacy coal ash plants. By going vertical, facilities can get more out of their limited space and keep a smaller footprint. The EnCAP-IT solution allows you to take things vertically and make better use of the land footprint. Additionally, it limits double handling during early excavation phases.

Stability

A solution needs to be stable, able to withstand time and elements. Our solution is more stable than traditional methods. We “bake in” greater stability every step of the way. As a component-based system, we “individually wrap” the berms or bunkers, making the stability calculations much more favorable.

EXCAVATE

SAFELY STORE