Project Costs Matter.

It is hard to believe that the massive push for CCR Environmental Management reform is all about the mighty dollar, but it is. Current arguments of this almost 12-year stakeholder battle have transcended to cost recovery, and who will pay for the CCR deposition methods. Like this wasn’t in the back of all stakeholders’ minds while everyone was arguing about the proper method.

The regulated utility reimbursement ratepayer mechanism has an unfortunate truth: ratepayers pay for good decisions and bad decisions. Rightly so, Utilities make money on capital deployment. So while stakeholders argue about a 9% or 10% return, everyone is missing the real question: does the capital project’s costs make sense? When it comes to CCR Management, there is barely enough time to analyze the project costs, scrutinize the proposal, and make everyone accountable. For example, if a state-run mandate requires a Closure by Removal with an estimated overall cost of $3.0B, has the question been answered as to why it is not a $2.5B or $2.0B price tag. As an industry, we should be looking for ways for ratepayers to pay for good decisions.

Here at EnCAP-IT, we take a slightly different twist on Project Costs Matter. We have developed tools to “manage the middle.” We try to save a percentage point here and there or stretch the project dollar to obtain more protections. You would think that it doesn’t mean much; however, a 2% decrease in costs by a small paradigm shift away from traditional methods becomes a big thing. That’s $60M in savings in a $3B project.

In our previous posts, we established the methods. We then graded and applied cost ranges to them. Now let’s look at how EnCAP-IT can help:

| Deposition Method | EnCAP-IT Solution Benefits |

On/Off Site |

Savings Range Potential (%)1 |

|---|---|---|---|

| Cap-In-Place | N/A | ON SITE | |

| Hybrid Cap-In-Place | safeBERM® assists in the consolidation of the ash by maximizing airspace creation, while repurposing the ash as construction material. Bi-directional hydrostatic protections proactively manage liquids within the berms and keep liquids from entering the berms. | ON SITE | 5% to 7% |

|

Beneficiation [Closure by Removal] |

Beneficiation Facilities are very capital intensive. By providing safeSTORAGE® to safely store future feedstock, the operating life of the plant is extended. This feature also significantly reduces capital unit costs. | ON SITE | 17% to 25% |

|

Structural Fill [Closure by Removal] |

By utilizing safeSTORAGE®; providing favorable geometry, existing coal ash basin footprint can be utilized, maximized, and consolidated away from floodplains. It becomes unnecessary to try and acquire additional property for landfill disposal, as well as getting local approval for that property. Structure can be modified to promote final end-use of ash. | ON SITE | 8% to 12% |

|

New Landfill [Closure by Removal] |

safeSTORAGE® assists in the disposal of the ash by maximizing airspace creation, while repurposing the ash as construction material. With Progressive Filling – the bunkers are created to manage unencumbered excavation. Maximizing excavation, decreases closure timeframes which lowers interim water treatment and other environment costs while the ash basin is “open”. | ON SITE | 8% to 12% |

|

Expansion of Existing Landfill [Closure by Removal] |

safeBERM® assists in the consolidation of the ash by maximizing airspace creation, while repurposing the ash as construction material. It becomes unnecessary to try and acquire additional property for landfill disposal, as well as getting local approval for that property. | ON SITE | 7% to 10% |

|

Basin Retrofit to Landfill [Closure by Retrofit] |

safeSTORAGE® component based; providing favorable geometry, existing coal ash basin footprint can be utilized, maximized, and consolidated away from floodplains. The bunkers are “individually wrapped”, making the stability calculations much more favorable. The stress on individual bunkers with interaction with adjacent bunkers is a lot less than one dam/levee’s stability for the entire structure. | ON SITE | 8% to 12% |

|

Beneficiation [Closure by Removal] |

With this strategy of end use of the ash, savings by the off-site owner can be “shared” with the Utility. | OFF SITE2 | 4% to 6% |

|

Structural Fill [Closure by Removal] |

With this strategy of end use of the ash, savings by the off-site owner can be “shared” with the Utility. | OFF SITE2 | Approx. 2% |

|

Landfill Disposal [Closure by Removal] |

NOT disposal but repurposed as construction fill to create more airspace at the receiving landfill. With this strategy of end use of the ash, savings by the off-site owner can be “shared” with the Utility. | OFF SITE2 | Approx. 2% |

1– Savings Range determined from projected and actual RFP cost models. Actual site-specific savings may vary; however, in all scenarios savings are possible.

2 – With off-site solutions the main savings reside with the site owner, however negotiations can yield some savings for the Utility.

As each deposition method is considered, we have identified solution tools to provide environmental safety and savings for our client. EnCAP-IT consistently looks at “the way things are” and innovates the solutions to “the way things could be” that are not only environmentally safe but economically feasible. Using the best tools is not cost-prohibitive.

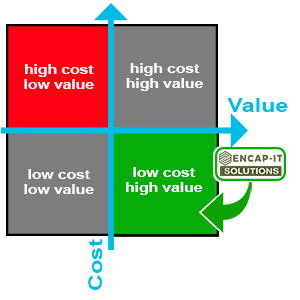

Throughout this blog series, we have analyzed the relationship between cost and value in CCR deposition methods. While the cost of the method is significant, the long-term value is equally crucial. With the economy in flux, the industry’s responsibility is to find a solution that brings the highest value at the lowest cost.

At EnCAP-IT, we operate in the low cost-high value quadrant. If paying for low value or overpaying for high cost doesn’t make sense to you, then we should talk. Come save with us!