The 5 C’s of Legacy Coal Ash Beneficial Reuse

When utilities are determining how to eliminate environmental hazards posed by legacy coal ash, the paramount goal should be to beneficially reuse much or all of it, if possible, with disposal being the last resort. We discussed methods of accomplishing this in Post 1: microencapsulation and macroencapsulation.

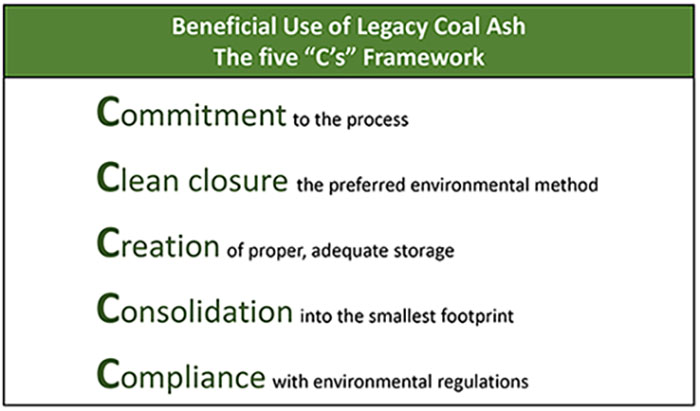

Now we’ll cover what these two methods’ frameworks have in common, or the “5 C’s” of beneficial reuse.

Beneficially reusing coal ash in productive ways yields many more benefits than simply disposing of this material. Coal ash may be used in place of some virgin materials in building products like concrete, brick, block and wall board, which helps to preserve virgin resources. Creating products through recycling typically requires less energy consumption in manufacturing, so fewer greenhouse gases are generated. Using coal ash as a construction fill in a macroencapsulated environment also yields similar benefits.

The 5 C’s Role in Coal Ash Beneficial Reuse

- Commitment to the process. In determining the best strategy for beneficial reuse, it’s vital for all parties involved to commit to carrying out the agreed-upon process, whose components include technology, cost and construct-ability.

- Clean closure, the preferred environmental method. Now that environmentalists and energy end users have become educated on the inherent dangers of leaving coal ash in the environment, they aren’t satisfied with a cap-in-place solution that leaves coal ash in unlined ponds where it can continue to leach toxins into the surrounding land and groundwater.

- Creation of proper, adequate storage. As already stated, dumping coal ash into unlined areas, or using it as unencapsulated fill material without environmental safeguards on construction sites are no longer considered viable options. Macroencapsulation uses the same landfill safeguards, rendering the storage proper and adequate.

- Consolidation into the smallest footprint. This has always been the mantra of the solid waste industry. In coal ash disposition, once as much volume is microencapsulated into other products as possible, remaining ash may be macroencapsulated as construction fill for berms or bunkers and rendered inert. Macroencapsulation can also reduce the footprint, which saves valuable acreage and can safely position the ash farther away from flood plains and groundwater. The bonus is that the surface created on the smaller footprint can be re purposed for solar energy generation or park land, to name a few uses. One notable example of land reuse is the famous Mount Trashmore in Virginia Beach. This 165-acre family-friendly park with many amenities was once a solid waste eyesore.

- Compliance with environmental regulations. Since coal ash has lost its classification as a benign byproduct of energy production, the EPA has issued guidelines for encapsulated and un-encapsulated beneficial reuse. Complying with or exceeding these regulations prohibits even the suggestion of implementing any legacy non-protective solutions.

Positive Outcomes Resulting from This Framework

- Correct the problem

- Beneficially reuse as much legacy coal ash as possible

- Re-purpose the land, if possible

- Safely remove all coal ash from the environment